Article

Why TOC Analysis Matters: Ensuring Water Purity In Pharma & Life Sciences

Dec 25, 2025

Enoch Daniel

Director

In pharmaceutical and life sciences manufacturing, water is not just a utility; it is a critical raw material. Whether used as Purified Water (PW), Water for Injection (WFI), or in cleaning, formulation, and analytical processes, the quality of water has a direct impact on product safety, regulatory compliance, and patient outcomes.

One analytical parameter stands at the center of water quality assurance:

Total Organic Carbon (TOC).

TOC analysis is not simply a compendial requirement; it is a scientifically robust, FDA-recognized indicator of organic contamination and a cornerstone of modern pharmaceutical water system monitoring.

Understanding TOC: The Scientific Foundation

Total Organic Carbon (TOC) represents the total amount of carbon bound in organic compounds present in water. Unlike tests that look for specific contaminants, TOC provides a comprehensive, aggregate measure of organic impurities, even at extremely low concentrations.

Because TOC measures total organic contamination, regardless of chemical identity, it is uniquely sensitive and capable of detecting impurities at parts-per-billion (ppb) levels, far beyond the reach of many conventional analytical tests.

The TOC measurement process involves three critical steps:

- Separation of Inorganic Carbon (IC)

- Carbonates and bicarbonates are removed, typically through acidification and degassing, ensuring they do not interfere with organic measurements.

- Oxidation of Organic Carbon

- All organic compounds are oxidized into carbon dioxide (CO₂).

- Detection of CO₂

- The resulting CO₂ is measured using highly sensitive detection methods, such as membrane conductometric detection, which provides a true representation of the organic load.

Why Organic Carbon Matters in Pharmaceutical Water

Regulatory pharmacopoeias such as USP, EP, JP, and IP define strict TOC limits (typically ≤500 ppb for PW and WFI). These limits exist for good reason. In practice, TOC is not just a purity test; it is an early warning system that enables proactive risk management.

Organic carbon in pharmaceutical water systems poses significant risks:

1. Microbial Growth & Biofouling

Organic compounds act as nutrients for microorganisms. Elevated TOC can accelerate microbial proliferation, biofilm formation, and endotoxin risks within water distribution loops.

2. Process & Product Interference

Organic contaminants may react with disinfectants, system materials, or product formulations, potentially generating unwanted by-products or compromising process efficiency.

3. Cleaning Validation Assurance

During CIP and cleaning validation, TOC is the preferred analytical tool for confirming the removal of organic residues, regardless of their chemical complexity or variability across products.

TOC from a Regulatory & FDA Perspective

Global regulators recognize TOC as a primary indicator of water system performance. FDA expectations and pharmacopeial standards emphasize not only measurement but also method validity, data integrity, and traceability. Analytical systems that assume or infer these values, rather than directly measuring them, introduce compliance risk.

Key regulatory expectations include:

1. Validated Analytical Methods

TOC analyzers must support qualification and validation in accordance with:

- USP <643> – Total Organic Carbon

- USP <1225> & <1226> – Validation and Verification of Compendial Procedures

- ICH Q2(R1) – Analytical Method Validation

2. True Carbon Measurement

Regulators expect true TOC measurement, including clear differentiation of:

- Total Carbon (TC)

- Inorganic Carbon (IC)

- Total Organic Carbon (TOC)

3. Data Integrity

Electronic records must comply with 21 CFR Part 11, ensuring the secure maintenance of audit trails, traceability, and trustworthy data suitable for regulatory review.

Why TRUE TOC and Data Integrity Matter

In an era increasingly shaped by data analytics, automation, and predictive maintenance, the value of TOC data extends far beyond compliance. However, data is only valuable if it is accurate, complete, and defensible.

If TOC data does not represent true TC, IC, and TOC, it is not meaningful for trend analysis, risk assessment, or regulatory confidence. This is why regulators, quality leaders, and engineers increasingly demand TRUE TOC, not inferred or partial measurements.

Sievers TOC Technology: Setting the Industry Benchmark

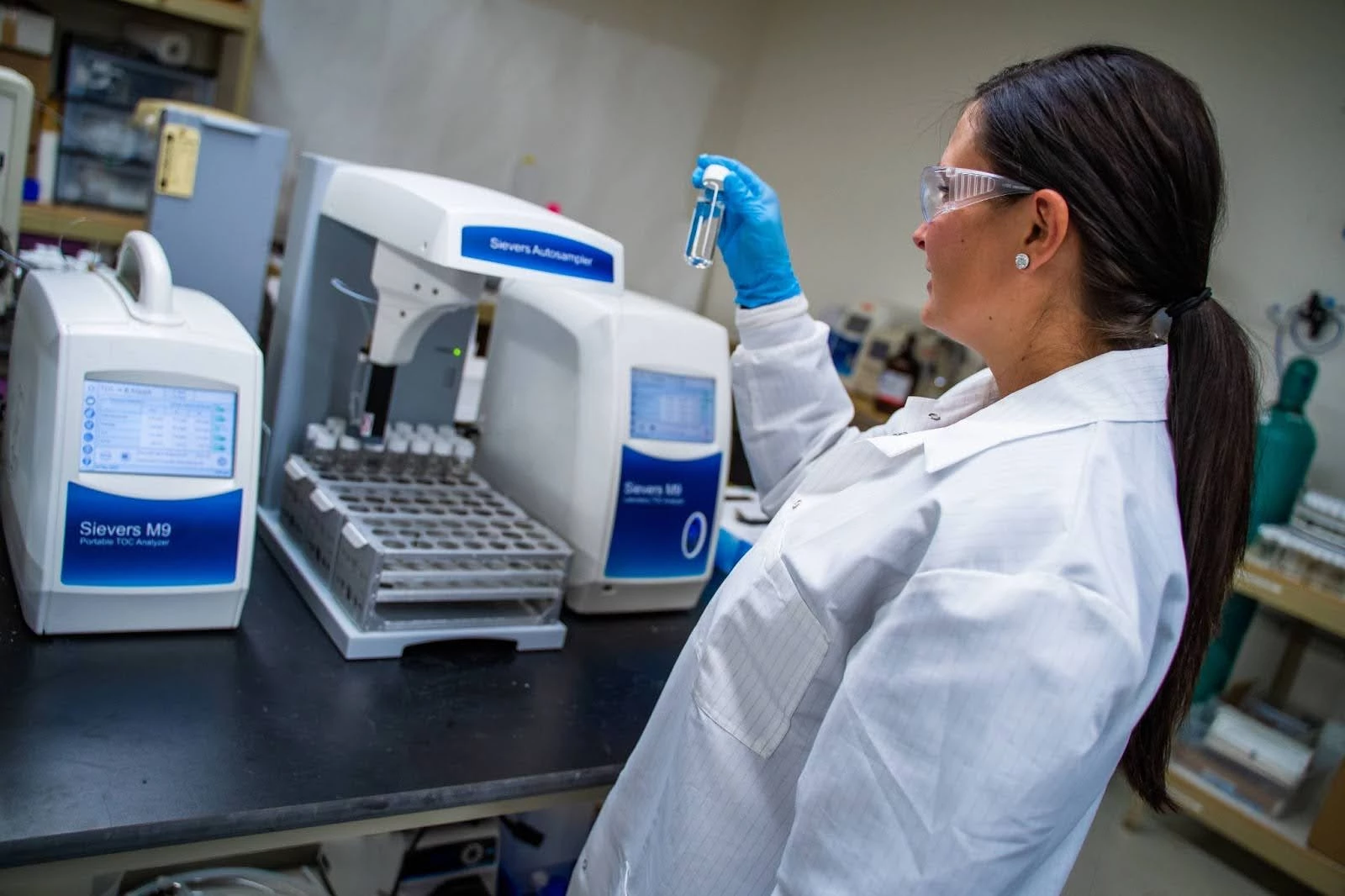

Sievers TOC Analyzers, distributed and supported in India by SVAN Analytical Instruments Pvt. Ltd., are globally recognized as the gold standard for monitoring pharmaceutical water.

What Sets Sievers Apart

- Membrane Conductometric Technology

Selectively measures CO₂ generated only from organic carbon, eliminating interference from inorganic ions and hetero-species.

- True Carbon Accounting

Direct measurement of TC, IC, and TOC is fully aligned with USP and JP requirements.

- Gasless, Reagent-Efficient Design

No combustion tubes, carrier gases, or high-temperature catalysts — resulting in higher reliability and lower maintenance.

- FDA & Global Regulatory Acceptance

Proven compliance with USP, EP, JP, IP, and FDA expectations across PW, WFI, and cleaning validation applications.

- Data Integrity by Design

21 CFR Part 11-ready architecture with secure audit trails and electronic records.

Practical Applications of TOC in Pharma & Life Sciences

1. Water System Monitoring (PW & WFI)

Continuous online TOC monitoring enables real-time oversight of water quality, ensuring rapid detection of deviations and improved system control.

SVAN offers advanced solutions such as Sievers M9 and M500 online TOC analyzers, optimized for high-purity water applications.

2. Cleaning Validation

TOC remains the most versatile and sensitive tool for cleaning validation, capable of detecting trace organic residues without prior knowledge of chemical composition.

3. Process Diagnostics & Troubleshooting

Portable TOC instruments, such as Sievers CheckPoint, allow rapid investigation across distribution loops, points of use, and during system commissioning or troubleshooting.

TOC as a Risk-Based Quality Tool

Under Quality by Design (QbD) and modern risk-based quality strategies, Facilities that embed high-quality TOC data into their quality intelligence frameworks gain not only compliance but also operational resilience.

TOC data plays a proactive role:

- Detects purification system degradation before product impact

- Enables trend-based predictive maintenance

- Identifies subtle changes linked to raw materials, seasonality, or equipment aging

Looking Ahead: TOC in the Age of Data & Analytics

As pharmaceutical manufacturing embraces digitalization, IoT, and advanced analytics, TOC data is becoming a key quality signal rather than a static test result.

Reliable TOC monitoring delivers:

- Reduced downtime

- Faster deviation resolution

- Greater audit confidence

- Improved patient safety

But this future depends on one principle:

Compliance is Black & White. Only TRUE TOC Counts. And Data Matters.

Conclusion

In pharmaceutical and life sciences manufacturing, water purity is non-negotiable.

TOC analysis remains the most scientifically rigorous and regulator-endorsed indicator of organic contamination.

With Sievers TOC analyzers, supported by SVAN Analytical Instruments Pvt. Ltd., manufacturers gain more than compliance, they gain confidence, control, and clarity in one of their most critical utilities.

FAQs

What is TOC analysis in pharmaceutical water?

TOC analysis measures total organic carbon to detect trace organic contaminants, ensuring PW and WFI systems meet pharmacopeial purity requirements.

Why is TOC critical for regulatory compliance?

TOC limits prevent microbial growth, contamination risks, and ensure water system integrity, making it a key FDA-recognized quality attribute.

How does TOC measurement work?

Inorganic carbon is removed, organic carbon is oxidized to CO₂, and the CO₂ is measured to quantify total organic contamination.

Where is TOC testing used?

Water system monitoring, cleaning validation, process control, and quality assurance.

What types of TOC analyzers are available?

Online continuous systems, portable analyzers, and laboratory instruments — selected based on application and compliance needs.